Rollout Lean & Six Sigma

The Business Excellence Network is your competent partner for the introduction of the Lean & Six Sigma philosophy in your company. We support you, your management and your employees throughout the entire process until the philosophy is implemented and lived in your company.

Lean is a philosophy that has to be lived by a company and its employees!

Mathias Hempe, Lean & Six Sigma

Lean & Six Sigma

Lean & Six Sigma is a management concept that combines the Lean philosophy with the methods of Six Sigma. This guarantees lean and fast processes und structures with a low error rate.

What is Lean Management?

Lean Management is a philosophy to eliminate redundant steps and optimize your processes to reach perfect harmony between them.

The goal is to produce the right product at the right time, in the right quantity and with minimal resources.

What is Six Sigma?

Six Sigma is a method to define, measure, analyze, improve and monitor business processes using statistical tools. The objective of Six Sigma is to reduce defects and increase quality and efficiency, and thus improve processes through targeted projects following a concrete phase plan.

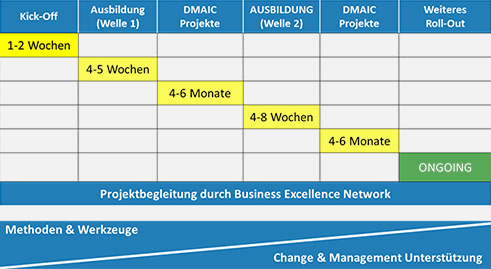

Lean & Six Sigma are implemented in a multi-step process. We support you, your management and your employees throughout this process.

Example: Lean Six Sigma (LSS) Rollout

The implementation process is complete – what now?

With the introduction of Lean & Six Sigma, your company has taken a big step towards lean processes. However, Lean & Six Sigma is not established with the completion of the rollout because Lean is a philosophy that has to be lived by the company and its employees. That is not always the case as the following statements prove:

Only one in eight change process is successful. One out of every fails.

Forbes

2/3 of all change processes fail according to MIT and Harvard Business School.

Forbes

To prevent this from happening in your company, we will be there for you at exactly this point.

We support you throughout the change process until the philosophy of Lean & Six Sigma really comes to life.

- Change in behavior of individuals: We develop your employees.

- Change in behavior in the organization: We develop your corporate culture.

- Transfer of knowledge regarding methods: We train you and your employees in the use of methods and tools.

If you follow this path with your company, you will be prepared for the future. Experience shows that in companies using both Lean and Six Sigma methods,

- cycle times can be reduced by 80%,

- costs can be decreased by 20 to 30%,

- and delivery times can be decreased by up to 60%.

The use of the Lean methods in product development

- reduces time to market by up to 50%,

- makes savings of 10 to 20% in material costs possible.

Are you ready to make the journey with us?

Consulting

Consulting